Why Choose Wire Sawing?

Mar/01/25

When it comes to cutting concrete, not all methods are created equal. If you’re dealing with thick slabs, reinforced structures, or need precision in tight spaces, wire sawing is the way to go. It’s fast, powerful, and—most importantly—it gets the job done right without wrecking everything around it.

Wire saws use diamond-embedded cables to slice through concrete, steel, and rebar like butter. It’s the go-to choice for contractors, engineers, and demolition crews who need efficiency without the headache.

What Is Wire Sawing?

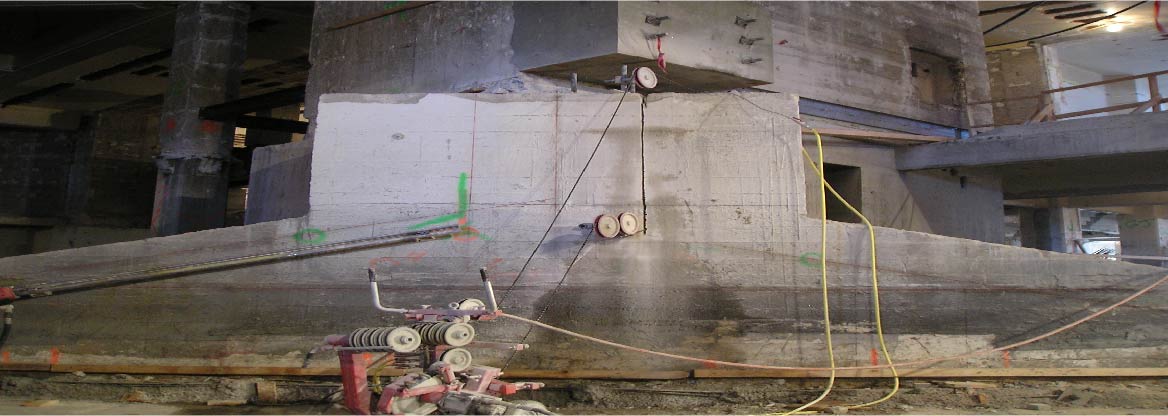

Wire sawing is the heavy hitter of concrete cutting. Unlike traditional saws with spinning blades, this method uses a high-tensile wire embedded with industrial diamonds to slice through concrete, steel, and rebar. The wire is looped around the material, powered by a hydraulic or electric system, and guided through a pulley system, which creates a continuous cutting motion that chews through even the toughest structures.

How is it Different from Other Cutting Methods?

Most concrete cutting methods—like wall sawing or flat sawing—rely on rigid circular blades. However, when you’re dealing with massive concrete structures, those saws hit their limits. Wire sawing, on the other hand, is designed for deep cuts, tight spaces, and awkward angles. It doesn’t care how thick the material is—it’ll slice through anything.

The Power of Diamond-Embedded Wire

Why diamonds? Because they’re one of the hardest materials on Earth. When industrial diamonds are embedded into the wire, they grind through concrete and steel without wearing down too quickly. That means cleaner cuts, less dust, and no overheating, which is a game-changer for big projects where precision and speed matter.

Key Advantages of Wire Sawing

When you’re cutting concrete, you want something fast, precise, and reliable—and that’s exactly what wire sawing delivers. It’s not just another method; it’s the go-to solution for jobs where traditional saws just don’t cut it (literally). Here’s why wire sawing is a game-changer in the concrete cutting world.

1. Precision Cutting with No Limits

Wire saws don’t have depth restrictions like traditional saw blades. Need to cut through a five-foot-thick concrete wall, perhaps for an elevator shaft installation or bridge pier modification? Wire sawing can handle these demanding tasks with precision. It’s also perfect for intricate projects like cutting underwater piers or segmenting massive concrete beams.

2. Minimal Vibration, Noise, and Dust

If you’re familiar with traditional concrete sawing, you’ll appreciate the innovation behind wire sawing. While traditional methods meet OSHA standards by using water to manage dust, wire sawing takes it a step further. It offers a quieter, vibration-free experience and minimizes dust without compromising safety. The wire moves smoothly through the material, creating little to no vibration, which means:

- Safer working conditions for crews.

- Lower noise levels, which is a huge plus in urban areas.

3. Faster and More Efficient Than Traditional Methods

Time is money, and wire sawing is tailored for efficiency. While the wire saw occasionally requires crimping due to jams or breaks, its continuous movement often allows for quicker cuts through thick or reinforced concrete.

4. Versatile for Any Project

One of the biggest advantages of wire sawing is its ability to cut from any angle. Unlike wall or floor saws that are limited by blade size and positioning, wire saws can be set up to cut:

- Vertically, horizontally, or diagonally.

- In tight spaces where big saws can’t fit.

- Underwater—yes, wire sawing works in submerged environments too.

5. Safer for Workers and the Job Site

Wire sawing offers a clean cutting option with significantly less airborne dust, thanks to its efficient design. This method not only keeps the job site cleaner but also reduces health risks for workers. Additionally, like our advanced wall saws, wire sawing can be operated remotely. This feature allows workers to manage the equipment from a safe distance, minimizing exposure to hazardous conditions and enhancing safety on the job site.

Bottom Line: Wire Sawing is the Smart Choice

If you need precision, speed, and versatility, wire sawing is the best option for the job.

How Wire Sawing Works

Wire sawing might sound high-tech, but at its core, it’s a simple yet powerful process. The combination of industrial diamond-coated wire, a hydraulic or electric power system, and a continuous cutting motion makes it one of the most efficient concrete cutting methods out there. Here’s how it all comes together.

Step-by-Step Process of Wire Sawing

- Setup – First, the wire saw is set up around the material that needs cutting. The wire is looped through a system of pulleys and tensioners, allowing it to move continuously. The positioning is customized depending on the shape, thickness, and location of the concrete.

- Wire Tensioning – To ensure smooth and precise cutting, the wire is tightened using a hydraulic system. Proper tension prevents the wire from slipping or losing effectiveness mid-cut.

- Cutting Begins – The saw is powered up, and the diamond wire starts rotating at high speed, grinding through concrete, rebar, and steel reinforcement. Unlike traditional saw blades that slice with brute force, wire sawing gradually erodes the material away, making for a cleaner, smoother cut.

- Cooling & Dust Control – To prevent overheating and keep dust levels low, water is continuously sprayed onto the cutting area. This keeps the wire running efficiently and reduces airborne debris, making the process safer for workers and the environment.

- Precision Finishing – Since wire sawing is computer-controlled or manually guided, the operator can make highly precise cuts without damaging nearby structures. Once the cut is complete, the wire loop is removed, and the concrete section can be lifted away.

Equipment Used in Wire Sawing

Wire saws rely on specialized, heavy-duty equipment to handle everything from small cuts to large-scale demolitions:

- Diamond Wire – The main cutting tool, reinforced with industrial diamonds for maximum durability.

- Hydraulic or Electric Drive System – Powers the movement of the wire, keeping it under consistent tension.

- Pulleys & Guide Wheels – Directs the wire along the cutting path for precision.

- Water Cooling System – Keeps the wire from overheating and minimizes dust.

Why This Process is So Effective

Wire sawing isn’t just about cutting through thick material—it’s about doing it with control, efficiency, and minimal disruption. Because the wire is flexible, it can be used in ways that traditional saws simply can’t match:

- It can cut through virtually any thickness—whether it’s 6 inches or 60 inches of solid concrete.

- It works in confined spaces where larger saws won’t fit.

- It delivers ultra-precise cuts without cracks or excessive debris.

Get a Free Quote Today

Need wire sawing for your next project? Let’s make it happen. With over 15 locations, 350+ employees, and a fleet of 400+ vehicles, A-Core Concrete Specialists are equipped to handle projects of any size and complexity.

Contact us today for a free quote and see how A-Core Concrete Specialists can help you get the job done right.